- Home

- Products ▾

- Packages ▾

- Supply Bundles ▾

- Arc Flash ▾

- Pipe Labeling ▾

- Articles ▾

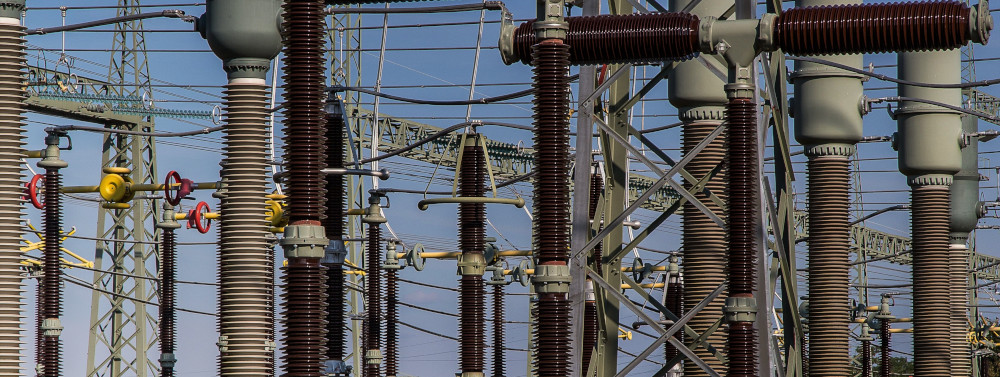

The electric industry is acutely aware of a phenomenon known as arc flash, a short circuit that passes through air between two live conductors, or between a live conductor and ground. This short circuit can be accompanied by incredible amounts of heat and pressure, and the results are often deadly. The frequency of reported incidents is on the increase, prompting increased awareness and action in the electric and safety industries.

Industrial Safety Solution provides a wide variety of arc flash labels, as well as number of arc flash label printing packages, which are used industry-wide to mitigate arc flash hazards through hazcomm labeling.

NFPA standards for arc flash are frequently updated. In 2021, the 70E standards were updated with additional detail and definitions, with clarifications to make the standard more easily understanable. Staying up-to-date with NFPA 70E standards will help your organization's arc flash hazard communication plan remain applicable.

Some of the basic NFPA 70E changes for 2021 include:

Arc flash can be caused from something as simple as approaching a high amperage source with a conductive object. Poorly maintained equipment or sub-standard parts may also trigger an arc flash. Missing insulation, corrosion or impurities on conductors may also cause arc flash to occur.

Arc flash injuries can be extremely severe. Intense heat, up to 35,000 degrees F, can cause fatal burns even when the victim is as much as 5 feet away from the source. Serious burns can still occur at up to 10 feet. With such extreme heat, metal can vaporize, causing additional hazards from molten droplets which can be propelled by the force of the flash. Finally, high intensity flashes can cause permanent eye damage resulting in blindness.

Arc flash has received significant industry attention in recent years. Before arc flash was understood, it was believed that electrical shock was the primary cause of all injuries in an electrical accident. While electrical shock does cause burns, the majority of all hospital admissions due to electrical accident related injuries are from arc flash. Industry professionals estimate that at least 5 to 10 arc flash explosions occur per day in the U.S. alone, resulting in approximately 1 to 2 deaths daily.

High energy faults can produce immense pressure and sound waves. This is known as an arc blast, and may accompany an arc flash accident. The pressure from such a blast can be hit a victim with as much as 2000 lb/sqft of pressure. This is enough pressure to propel metal objects at several hundred miles per hour, or even knock down walls.

"This standard addresses those electrical safety requirements for employee workplaces that are necessary for the practical safeguarding of employees."

The NFPA 70E standard contains vital information on arc flash labeling and signage, to help in avoiding accidents involving arc flash. Because

accidents cannot be prevented without awareness, proper hazard identification through labeling is critical to NFPA 70E compliance.

More information is available from:

www.nfpa.org NFPA 70E information

Arc Flash Training Resources

The NEC, also known as NFPA 70E, contains vital information on proper electrical installations, including information on properly marking hazards. The latest revision includes information on labeling compliance and arc flash hazards.

NFPA 70E outlines responsibilities that facilities have in regards to arc flash safety:

More information is available from:

www.nfpa.org NFPA NEC 70E information

Arc Flash Training Resources

OSHA standards 29 CFR 1910.333(a), electrical standard number 1910.333 covers the importance of

"safety-related work practices [that] shall be used to protect employees who may be exposed to the electrical hazards."

Compliance with OSHA standards through proper labeling will ensure increased safety, and this part of the OSHA standards

provides insights into the importance of that effort.

More information is available from:

www.osha.gov 1910.333 information

Arc Flash Training Resources

OSHA is increasingly aware of the occupational hazards associated with arc flash, and is beginning to cite workplaces that do not meet regulation for appropriate labeling of arc flash hazards. OSHA refers people to the NFPA 70 and 70E standards for information on how to best label arc flash hazards.

Industrial Safety Solutions offers a variety of OSHA compliant arc flash labels, pre-made ANSI z535 labels and general safety labels. These labeling products, combined with our industrial thermal transfer labeling system, provide a platform for NFPA 70 and NFPA 70E compliant arc flash labeling.

Additional information on arc flash hazards can be found at the NFPA and OSHA websites. They are referenced here for your convenience.

NFPA

http://www.nfpa.org

OSHA

http://www.osha.gov

Arc Flash Training Resources